Cnc Drill Line Arguments

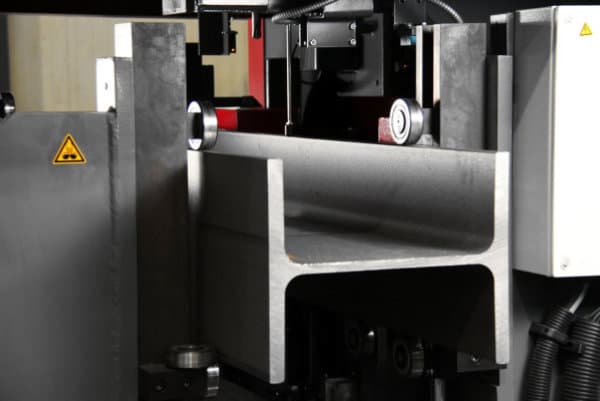

Let's take a look at how Insert Drill bits and Twist Drill Bits work in real-life fabrication situations. This is the most popular drilled hole diameter.

CNC Drill Line supports DXF files import and can be used to create 3-D models as long as the steel details are followed precisely. Some of these rules may be different from the one you are using at the moment, and may require some adjustment. This is not as easy as using 3-D modeling software.